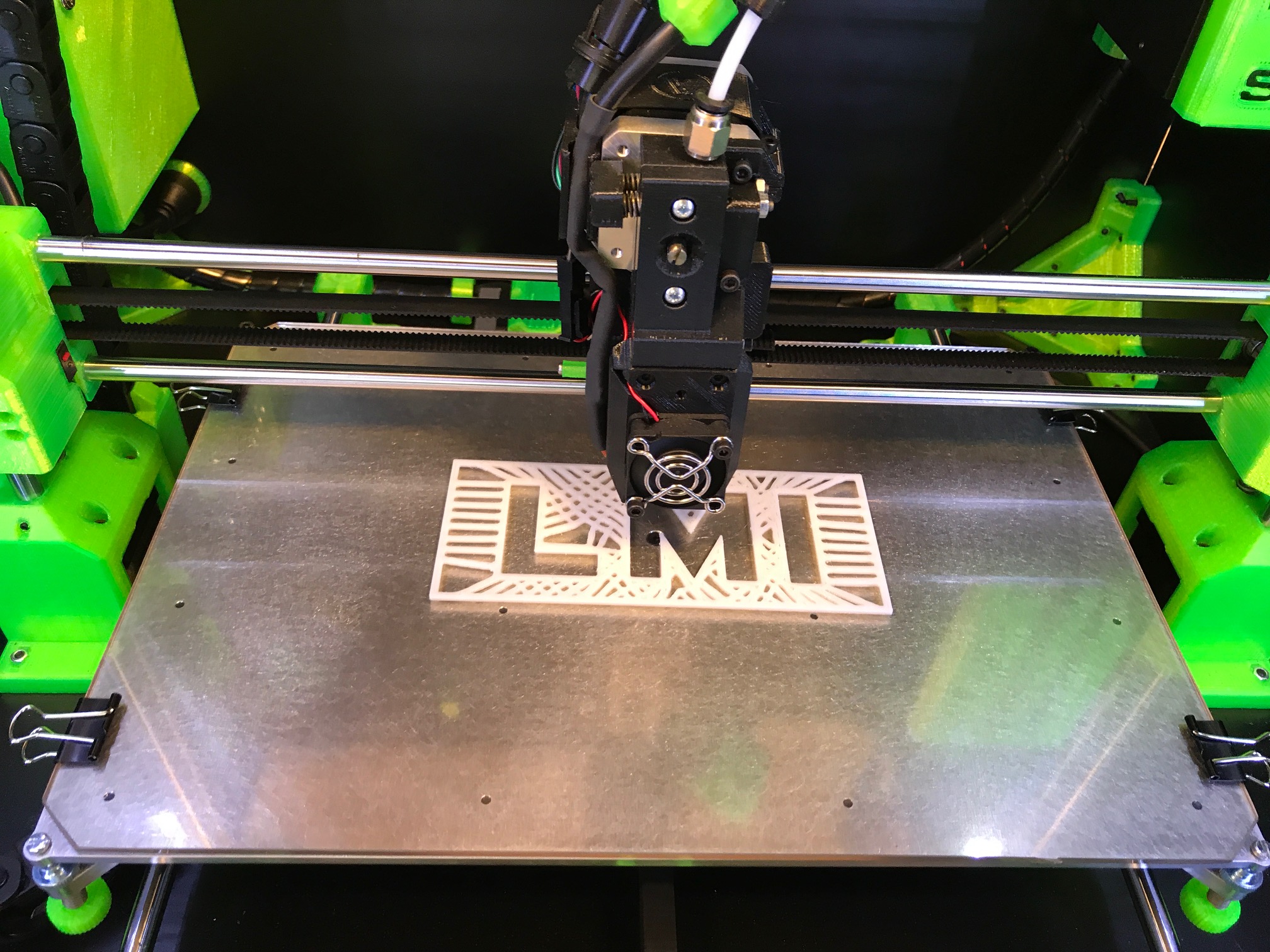

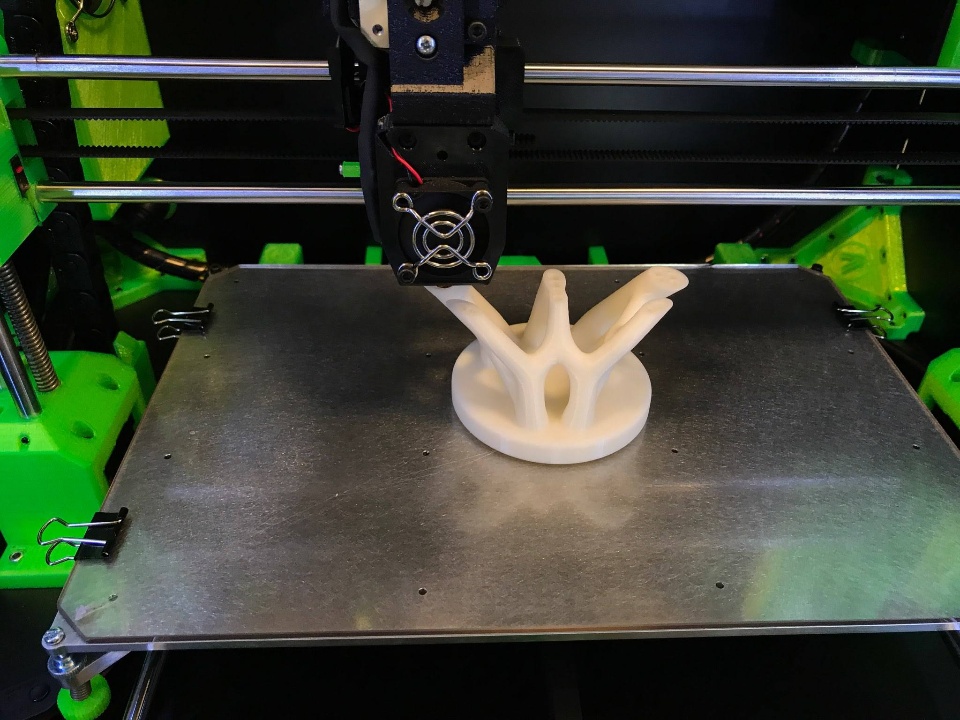

3D printing / Additive manufacturing

FabLab @ LMI EA 3226, INSA Rouen

|

|

|

Contact: C. Gout

Modélisation Mathématique avancée et Simulations Numériques

pour l'innovation dans l'environnement et la santé

M2SiNum (2018-2021)

![]()

3D printer, FabLab @ LMI EA 3226, INSA Rouen

3D printer, FabLab @ LMI EA 3226, INSA Rouen

By Martin Pierre Schmidt and Christian Gout (LMI, INSA Rouen)

The designs were automatically generated using Topology Optimization algorithms.

In recent years, the field of additive manufacturing (AM), often referred to as 3D printing, has seen tremendous growth and radically changed the way we describe valid 3D models for fabrication. While not free of constraints, AM offers an unprecedented level of freedom in geometrical complexity for manufacturable feasible designs. One example of such design freedom is the creation of intricate, robust, and lightweight internal structures. Our approach builds upon and extends the recent works on topology optimization for the so-called infill structures. In order to have more design control over these infill structures, we present a new formulation allowing the generation of mixed design patterns containing bulk and porous regions using a guiding constraint parameterized by non-uniform constraining fields. Secondly, we demonstrate multiple methods of generating such non-uniform fields to leverage the present formulation and analyze their effect on the geometrical and physical properties of the obtained designs.

Major reference:

M.P. Schmidt, C. Pedersen, C. Gout, On structural topology optimization using graded porosity control, Structural and Multidisciplinary Optimization (60 - 4), pp. 1437--1453, 2019.

and

M.-P. Schmidt, L. Couret, C. Gout, C. B.W. Pedersen, Structural Topology Optimization with Anisotropic Materials for Continuous Fiber Designs, Structural and Multidisciplinary Optimization 62, pp. 3105–3126, 2020.

Christian Gout - Nov. 2019